Kayan ado

Lokacin yin kayan ado, yanzu ana amfani da abubuwa daban-daban, musamman ma ƙarfe masu daraja da gami.A al'adance, masana'antar ta yi amfani da hanyoyi da yawa kamar sassaƙa (samar da injina) ko etching.A baya, wani muhimmin dalili na yin zinare a kan ayyuka masu tsada shine don keɓance su ko ƙara rubutu masu ma'ana.A yau, zane-zane na kayan ado na kayan ado, ciki har da filin kayan ado na kayan ado, ya zama mafi mahimmanci.Tare da fasahar Laser, ana iya amfani da karafa masu daraja kamar ƙarfe na Laser da duk sauran karafa.

Da ke ƙasa akwai 'yan abũbuwan amfãni na Laser sabon inji idan aka kwatanta da gargajiya sabon hanyoyin:

Karamin murdiya akan sassa saboda ƙaramin yanki da zafi ya shafa

Yanke sashi mai rikitarwa

kunkuntar kerf nisa

Maimaituwa sosai

Tare da tsarin yankan Laser zaka iya ƙirƙirar ƙayyadaddun tsarin yankan don ƙirar kayan adonku:

Monograms masu tsaka-tsaki

Da'irar Monograms

Sunan Abun Wuya

Hadaddiyar Tsare-tsare na Musamman

Pendants & Laya

Matsaloli masu rikitarwa

Sassan-Na-A-Kind Na Musamman

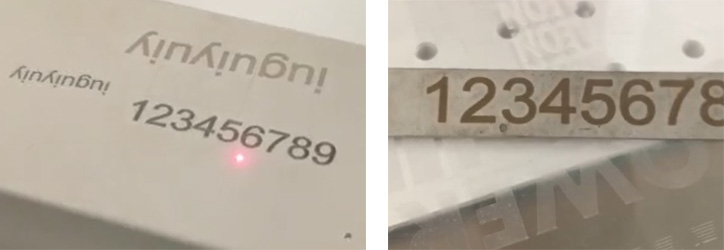

Bar code

Laser ya zana lambobin mashaya, lambobi, da tambura tare da tsarin Laser AEON.Layukan layi da 2D, kamar lambobin serial, an riga an yi amfani da su a yawancin masana'antu, kamar (misali masana'antar kera motoci, fasahar likitanci, ko masana'antar lantarki), domin a iya gano samfura ko sassa ɗaya.Lambobin (mafi yawan matrix bayanai ko lambobin mashaya) sun ƙunshi bayanai game da kaddarorin sassan, bayanan samarwa, lambobin tsari da ƙari mai yawa.Irin wannan alamar ɓangaren dole ne a iya karanta shi cikin sauƙi kuma a wani ɓangare kuma ta hanyar lantarki kuma yana da dorewa mai dorewa.Anan, alamar laser yana tabbatar da kasancewa mai sassauƙa da kayan aiki na duniya don kayan aiki iri-iri, siffofi da girma da kuma sarrafa bayanai masu ƙarfi da canzawa.Sassan suna da alamar Laser a mafi girman gudu da cikakkiyar daidaito, yayin da lalacewa ba ta da yawa.

Tsarin Laser ɗinmu na fiber ɗinmu kai tsaye ya zana ko alama kowane ƙarfe ko mai rufi wanda ya haɗa da bakin karfe, ƙarfe na kayan aiki, tagulla, titanium, aluminum da ƙari mai yawa, yana ba ku damar ƙirƙirar nau'ikan alama iri-iri a cikin ɗan lokaci!Ko kana zana yanki ɗaya a lokaci ɗaya ko tebur mai cike da abubuwan haɗin gwiwa, tare da tsarin saitin sa mai sauƙi da madaidaicin ikon yin alama, Laser fiber shine kyakkyawan zaɓi don zanen lambar lambar al'ada.

Tare da injin yin fiber, zaku iya sassaƙa kusan kowane ƙarfe.ciki har da bakin karfe, kayan aikin injin karfe, tagulla, fiber carbon, da ƙari.

Harshen waya

Yayin da wayar tafi da gidanka ke kara kaifin basira da sauki da sirara, ana ci gaba da kara habaka lahani na fasahar kere-kere ta gargajiya, kuma an samu nasarar shigar da fasahar sarrafa Laser a cikin masana'antar kera wayar hannu, kuma cikin sauri ta zama abin so. masana'antar kera wayar hannu.Idan aka kwatanta da na gargajiya inkjet aiki, Laser engraving yana da abũbuwan amfãni daga high engraving daidaici, wadanda ba lamba, m, anti-jebu da high aiki yadda ya dace.

Bayanan samarwa, lambar haƙƙin mallaka da sauran nau'ikan bayanan bayanan da ke kan harsashi na baya na wayar hannu kaɗan ne.Sana'a na gargajiya na iya saduwa da bukatun ƙananan haruffa, kuma na'urar yin alama ta Laser yana da ƙaramin wuri mai mayar da hankali.Dangane da buƙatu daban-daban, ƙaramin hali na iya zama 0.1mm.A ƙasa, kun cancanci sabbin buƙatu.Haɓaka casing ɗin wayar hannu kuma ya sami gogewa na robobi, aluminium anode, yumbu, bawo mai ƙarfe, gilashi da sauran kayan.Daban-daban na Laser alama inji ana amfani da daban-daban kayan.Misali, robobi na amfani da karin Laser UV ultraviolet, yayin da anode aluminum da ceramics An yi amfani da na'ura mai alamar fiber Laser pulsed, kuma an gwada alamar gilashin da farko, amma an yi watsi da shi.

Fa'idodin fasahar sarrafa Laser Laser a kan casing wayar hannu: Laser zanen zanen Laser abu ne mai dogaro sosai.Alamar zane-zane, haruffa, lambobi masu mahimmanci, bayyanannun kuma masu jurewa, ba aikin sadarwa bane, don haka aikin da aka sarrafa ba ya lalace ko ya lalace.Laser Laser engraving kwamfuta zane, typeetting, kimiyya.Ana iya bincika tambarin da ake buƙata bisa ga tambarin da abokin ciniki ya bayar;serial number gaba ɗaya an yi ta atomatik.

Bugu da kari, Laser engraving yana da karfi anti-jabu yi.Ka sanya samfuranka su zama masu saurin kamuwa da jabu, kayayyaki na gaske, kuma dole ne su fi shahara.Gudun zane-zane yana da sauri kuma lokaci yana da ƙarfi, wanda ke inganta ingantaccen samarwa.Hoton Laser Laser yana da kyau, kyakkyawa kuma yana da godiya mai ƙarfi.Alamar alama tana da daidaitattun alamar alama, kyakkyawan bayyanar, bayyanar karimci da tasirin kallo mai kyau.

Kayan daki

A cikin 'yan shekarun nan, a cikin masana'antun masana'antu, fasahar laser kuma an yi amfani da shi don yankan da sassaka, wanda ya sami sakamako mai kyau kuma ya inganta inganci da ingantaccen aiki na masana'anta.

Akwai hanyoyi guda biyu don yin aiki tare da fasahar laser a cikin tsarin masana'antar kayan aiki: zane da yankan.Hanyar sassaƙawa tana kama da ƙwanƙwasa, wato, aikin da ba ya shiga.Zane don tsari da rubutu.Za'a iya sarrafa zane-zane masu alaƙa da kwamfuta don aiwatarwa mai girma biyu, kuma zurfin zane na iya kaiwa fiye da mm 3 gabaɗaya.

Ana amfani da yankan Laser galibi wajen kera kayan daki don yankan veneer.MDF veneer furniture shine babban kayan daki na zamani na zamani, ba tare da la'akari da kayan kayan zamani na zamani ko kayan aikin panel na zamani ta amfani da samar da kayan kwalliyar MDF shine yanayin ci gaba.Yanzu yin amfani da inlays na veneer na launi daban-daban da laushi a cikin samar da kayan aikin zamani na zamani ya samar da kayan da aka tsara dalla-dalla, wanda ya inganta dandano na kayan daki, kuma ya kara yawan kayan fasaha na kayan aiki da karuwar riba.sarari.A da, yankan labulen an yi amfani da shi da hannu ta hanyar zawar waya, wanda ke ɗaukar lokaci da aiki, kuma ba a tabbatar da ingancinsa ba, kuma farashin yana da yawa.Yin amfani da veneer-yanke Laser yana da sauƙi, ba kawai ninka ergonomics ba, har ma saboda diamita na laser har zuwa 0.1 mm kuma yankan diamita akan itacen kusan 0.2 mm ne kawai, don haka tsarin yankan ba shi da misaltuwa.Sa'an nan kuma ta hanyar aikin jigsaw, manna, gogewa, zane-zane, da dai sauransu, haifar da kyakkyawan tsari a saman kayan daki.

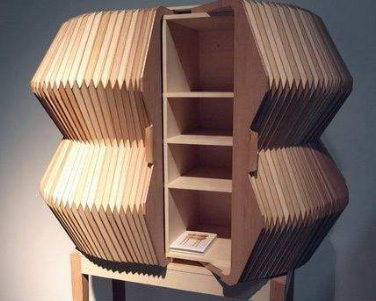

Wannan "accordion cabinet" ne, babban Layer na majalisar ya nade kamar accordion.Gilashin katako na Laser an haɗa shi da hannu zuwa saman masana'anta kamar Lycra.Haɗin haɗaɗɗiyar waɗannan abubuwa guda biyu yana sa saman katakon katako mai laushi da na roba kamar zane.Fatar mai kama da accordion tana rufe kabad ɗin rectangular, wadda za a iya rufe ta kamar kofa lokacin da ba a amfani da ita.

Label mutu cutter

Fasahar da ta kasance baƙon ƙunƙuntar masana'antar buga alamar gidan yanar gizo ba da daɗewa ba tana ci gaba da ganin haɓakar dacewa.Yankewar mutuwar Laser ya fito azaman zaɓi mai dacewa ga masu juyawa da yawa, musamman tare da yaduwar gajeriyar bugu na dijital.

Tutar tuta

A matsayin kyakkyawan kayan nunin nuni, ana amfani da tutocin talla da ƙari a cikin ayyukan tallan kasuwanci daban-daban.Kuma nau'ikan tutoci kuma sun bambanta, tutocin allurar ruwa, tutar rairayin bakin teku, tutar kamfani, tuta na gargajiya, tuta, tuta, tutan gashin tsuntsu, tutar kyauta, tuta mai rataye da sauransu.

Yayin da buƙatun tallace-tallace ke zama mafi keɓancewa, keɓantattun nau'ikan tutocin talla suma sun ƙaru.Canja wurin zafi na ci gaba da fasahar bugu na dijital a cikin tallace-tallacen banner na al'ada sun yi rinjaye, amma ba su daidaita ba har yanzu babban yankewa ne.

Injin mu suna da kyau sosai a yankan girman daban-daban da tutar firam bisa ga buƙatun abokin ciniki.Yana taimakawa rage samarwa da aiki ga masana'antun gargajiya, inganta yawan aiki da ƙimar ingancin samfur.

Kafet

Kafet da aka yi amfani da shi sosai a wuraren zama, otal-otal, filayen wasanni, dakunan nunin, motoci, jiragen ruwa, jiragen sama da sauran rufin bene, akwai raguwar amo, rufin zafi da tasirin ado.

Kafet na gargajiya gabaɗaya ana amfani da yankan hannu, yanke wutar lantarki ko yanke Die.Gudun yankan ga ma'aikata yana da jinkirin jinkirin, ba za a iya tabbatar da daidaiton yankewa ba, sau da yawa yana buƙatar yankan na biyu, samun ƙarin kayan sharar gida;amfani da yankan wutar lantarki, saurin yankan yana da sauri, amma a cikin sarƙaƙƙiyar ginshiƙan zane-zane, saboda ƙuntatawa ta hanyar lanƙwasa, sau da yawa suna da lahani ko ba za a iya yanke ba, kuma suna da sauƙin gemu.Yin amfani da yankan mutuwa, yana buƙatar yin ƙirar da farko, kodayake saurin yankewa yana da sauri, don sabon hangen nesa, dole ne ya yi sabon ƙirar, yana da tsada mai tsada don yin ƙirar, dogon zagayowar, ƙimar kulawa mai girma.

Laser yankan ne da ba lamba thermal aiki, abokan ciniki kawai kawai load da kafet a kan aiki dandali, da Laser tsarin za a yankan bisa ga juna tsara, da mafi hadaddun siffofi za a iya sauƙi yanke.A lokuta da yawa, Laser yankan na roba kafet ba shi da kusan wani coked gefe, gefen zai iya ta atomatik hatimi, don kauce wa matsalar gemu.Abokan ciniki da yawa sun yi amfani da injin yankan Laser ɗin mu don yanke kafet na motoci, jirgin sama, da kafet ɗin yankan kofa, duk sun amfana da wannan.Bugu da ƙari, aikace-aikacen fasahar laser ya buɗe sababbin nau'o'in masana'antar kafet, wato kafet da aka zana da kafet inlay, samfuran kafet ɗin da aka bambanta sun zama samfuran al'ada, masu amfani suna karɓar su sosai.(Laser na zinariya)

Motar ciki

A cikin mota ciki (yafi yawan murfin kujerar mota, kafet, jakunkunan iska, da sauransu) wuraren samarwa, musamman samar da kushin mota, babban hanyar yankan kwamfuta da yankan hannu.Yayin da farashin yankan na'ura mai kwakwalwa ya yi tsada sosai (farashi mafi ƙanƙanci ya fi Yuan miliyan 1), fiye da ƙarfin sayayya na gabaɗaya na masana'antun masana'antu, kuma yana da wahalar yanke na musamman, don haka ƙarin kamfanoni suna amfani da yankan hannu.Amma injin laser Aeon babban zaɓi ne.

Bayan amfani da injin yankan Laser na AEON, lokacin da injin zai yanke saitin kujeru ya ragu zuwa mintuna 20.Kamar yadda yin amfani da tsarin rubutu na hankali, asarar kayan abu kuma yana raguwa sosai, kuma yana kawar da farashin aikin da aka yanke, don haka farashin yana raguwa sosai.Haɗe tare da aikace-aikacen tsarin ciyarwa ta atomatik, yana samar da ingantaccen samarwa yana ƙaruwa da kashi ɗaya bisa uku.Yayin da nau'in software da aka saka, yana samar da nau'i na sauƙi don canza fasalin, tsarin samfurin ya inganta sosai, sababbin samfurori suna fitowa a cikin rafi marar iyaka;A cikin tsari, da Laser sabon, hakowa, engraving da sauran m fasaha hadewa wanda ƙwarai ƙara darajar-kara kayayyakin, da kuma kai da mota ciki sarrafa fasaha na sabon fashion, da m rejuvenation na Enterprises.

Kafofin watsa labarai na tacewa

Tacewa shine muhimmin tsarin kula da muhalli da aminci.Daga masana'antar gas mai ƙarfi, rabuwar gas-ruwa, rabuwa mai ƙarfi, rabuwa mai ƙarfi, tsaftace iska ta yau da kullun da tsabtace ruwa na kayan aikin gida, tacewa ya zama mafi girma.Aiwatar zuwa yankuna da yawa.Takamaiman aikace-aikace kamar masana'antar wutar lantarki, masana'antar siminti, masana'antar siminti, da dai sauransu, masana'antar yadi da sutura, tacewa iska, kula da najasa, tacewa sinadarai da crystallization, iskar masana'antar kera motoci, matatun mai da na'urorin sanyaya iska, injin tsabtace gida, da sauransu.

Babban kayan tacewa sune kayan fiber, kayan saƙa da kayan ƙarfe, musamman kayan fiber da aka fi amfani da su, galibi auduga, ulu, lilin, siliki, viscose, polypropylene, nailan, polyester, acrylic, nitrile, fiber na roba, da sauransu.Da kuma fiber gilashi, fiber yumbu, fiber na karfe, da makamantansu.

Na'urorin yankan Laser sun fi sauri da inganci fiye da hanyoyin gargajiya.Yana iya yanke kowane nau'i na siffofi a lokaci guda.Mataki ɗaya kawai don cimma shi kuma babu buƙatar sake yin aiki.Sabbin injunan suna taimaka muku adana lokaci, adana kayan aiki da adana sarari!

Yanke katako

Tare da yankan AEON da injin sa hannu, zai sauƙaƙe tsarin aikin ku da sauri.Tare da taimakon injin Aeon guda ɗaya kawai, zaku iya yin yankan, zane ko sanya alama akan itace a juzu'i ɗaya ba tare da taimakon wasu injuna ba.

Yanke itace da zane-zane sune biyu daga cikin shahararrun aikace-aikacen laser saboda suna iya kewaye da ayyuka daban-daban.Daga cikin kayan aiki zuwa firam ɗin hoto zuwa hannayen wuka, ana amfani da tsarin Laser na AEON a kusan kowane nau'in aikin katako da zaku iya wucewa.Ko kuna aiki tare da katako, veneers, inlays, mdf, plywood, goro, alder, ko ceri, zaku iya zana hotuna masu ban mamaki tare da tsarin laser.

Yanke zanen itace zuwa nau'i daban-daban da tsayi daban-daban shine kawai guntun biredi tare da taimakon injin yankan laser mu.Ƙirar ƙofar mu ta musamman za ta taimake ka ka magance dogon kayan abincin dare.zaka iya yanke tsayin itace mara iyaka ko da ba tare da babban injin ba.

Lokacin da kuke buƙatar ƙara wasu kayan ado zuwa samfuran ku na katako kamar firam ɗin hoto na itace, akwatin katako, tsefe na katako ko ƙofofin katako, abin yankan Laser ɗin mu na AEON zai juya zuwa injin zanen Laser na itace don taimaka muku.Abu ne mai sauqi da dacewa don zana tamburan ku, hotuna na sirri da rubutu zuwa samfuran katako na ku ta amfani da injin zanen Laser AEON.

Godiya ga na'ura na Laser, ba dole ba ne ka raba zanen Laser na itace da yankan Laser zuwa sassa biyu.Yanzu zaku iya yin waɗannan ayyuka daban-daban guda biyu a juzu'i ɗaya!Hakanan za'a iya yin zane-zanen 3D yanzu!

Kumfa

Injin Laser AEON ya dace sosai don yanke kayan kumfa.Kamar yadda yake yanke ta hanyar da ba ta sadarwa ba, don haka ba za a sami lalacewa ko lalacewa a kan kumfa ba.Kuma zafi na co2 Laser zai rufe gefen lokacin yankan da zane don haka gefen ya kasance mai tsabta da santsi wanda ba lallai ne ku sake sarrafa shi ba.Tare da kyakkyawan sakamako na yanke kumfa, ana amfani da na'urar laser don yanke kumfa a wasu aikace-aikacen fasaha.

Kumfa da aka yi da polyester (PES), polyethylene (PE) ko polyurethane (PUR) sun dace sosai don yankan Laser, zanen Laser.Ana amfani da kumfa don saka akwatuna ko manne, da kuma hatimi.Baya ga waɗannan, Laser yanke kumfa kuma ana amfani da shi don aikace-aikacen fasaha, kamar abubuwan tunawa ko firam ɗin hoto, misali.

Laser kayan aiki ne mai sassauƙa sosai: Komai mai yiwuwa ne, daga ƙirar samfuri har zuwa jerin samarwa.Kuna iya yin aiki kai tsaye daga shirin ƙira, wanda yake da mahimmanci musamman a fannin saurin samfuri.Idan aka kwatanta da hadaddun ruwa jet sabon tsari, da Laser ne muhimmanci sauri, mafi m kuma mafi inganci.Yanke kumfa tare da injin Laser zai samar da tsaftataccen haɗe da gefuna.

Guda biyu launi ABS

ABS biyu allo allo nau'in takardar ABS ne.Ana amfani da shi sosai a kasuwa.Hakanan ana samunsa ta nau'ikan iri da yawa.Ana iya raba shi zuwa nau'i biyu: cikakken allo mai launi biyu, allon karfe mai launi biyu da katako mai launi biyu na fasaha.

ABS--AEON Laser-mira jerin na iya amfani da su don yanke ABS Launi biyu tare da saurin yankan sauri da kyakkyawan sakamakon yanke.Tabbas, ingancin yankan galibi ya dogara ne akan ikon yankewa da sauri.

Tsarin yankan Laser na iya yanke nau'ikan ABS iri-iri na kauri daban-daban kuma sun dace sosai don ƙirƙirar sifofi masu rikitarwa.Sakamakon zane-zane akan launi biyu ABS shima yana da inganci.Abokan ciniki da yawa suna son amfani da shi don sassaƙa haruffa da tambura akan faranti na ABS Launi Biyu da sigina.Idan aka kwatanta da hanyoyin gargajiya, yankan Laser da zane ya fi sauƙi, sauri, mafi inganci kuma mafi daidai.