Ubucwebe

Xa kusenziwa ubucwebe, kusetyenziswa izinto ezininzi ezahlukeneyo ngoku, ingakumbi iintsimbi ezixabisekileyo kunye nealloys.Ngokwesiko, ishishini lisebenzise iindlela ezininzi ezinjengokukrola (ukuveliswa koomatshini) okanye ukukrolwa.Ngaphambili, esona sizathu sibalulekileyo sokwenziwa kwegolide kwimisebenzi ebiza imali eninzi yayikukuzenzela wena okanye ukongeza imibhalo enentsingiselo.Namhlanje, uyilo loyilo lobucwebe, kubandakanywa nentsimi yobucwebe befashoni, iba yinto ebaluleke ngakumbi.Ngobuchwepheshe be-laser, iintsimbi ezixabisekileyo ezifana neentsimbi ze-laser kunye nazo zonke ezinye iintsimbi zingasetyenziswa.

Apha ngezantsi kukho iingenelo ezimbalwa zoomatshini bokusika i-laser xa kuthelekiswa neendlela zokusika zemveli:

Ukugqwetheka okuncinci kwiindawo ngenxa yendawo encinci echaphazelekayo yobushushu

Ukusika inxalenye entsonkothileyo

Ububanzi be-kerf emxinwa

Ukuphindaphinda okuphezulu kakhulu

Ngenkqubo yokusika i-laser unokwenza ngokulula iipateni zokusika ezintsonkothileyo kuyilo lwakho lobucwebe:

IiMonograms ezinxibelelanayo

Isangqa seeMonograms

Igama leNecklaces

Uyilo oluntsonkothileyo lweSiko

Izidanga kunye namakhubalo

Iipateni ezintsonkothileyo

Iinxalenye zesiko enye-ye-A-Uhlobo

Ibhakhowudi

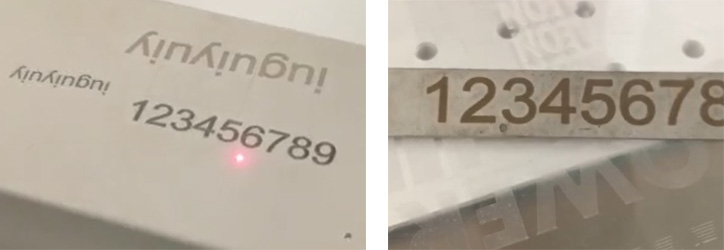

I-Laser ibhala iikhowudi zakho zebha, iinombolo zesiriyali, kunye neelogo ngenkqubo yeLaser yeAEON.Umgca kunye neekhowudi ze-2D, njengamanani e-serial, sele esetyenziswa kumashishini amaninzi, afana (umz. ishishini leemoto, ubuchwepheshe bezonyango, okanye ishishini lombane), ukuze kwenziwe iimveliso okanye iindawo ezizimeleyo.Iikhowudi (ubukhulu becala i-matrix yedatha okanye iikhowudi zebha) ziqulethe ulwazi malunga neepropati zamalungu, idatha yokuvelisa, iinombolo zebhetshi kunye nokunye okuninzi.Oko kumakishwa kwecandelo kufuneka kufundeke ngendlela elula kwaye ngokuyinxenye nangobuchwephesha be-elektroniki kwaye kube nokuhlala ixesha elide.Apha, ukumakishwa kwe-laser kubonakalisa ukuba sisixhobo esiguquguqukayo kunye nehlabathi jikelele kwiintlobo ezininzi zemathiriyeli, iimilo kunye nobukhulu kunye nokusetyenzwa kwedatha eguqukayo kunye nokutshintsha.Amacandelo aphawulwe nge-laser ngesantya esiphezulu kunye nokuchaneka ngokupheleleyo, ngelixa ukunxiba kuncinci.

Iinkqubo zethu ze-fiber laser zikrola ngokuthe ngqo okanye ziphawule nayiphi na intsimbi engenanto okanye egqunywe ngentsimbi, isixhobo sentsimbi, ubhedu, i-titanium, i-aluminiyam kunye nokunye okuninzi, okukuvumela ukuba wenze iindidi zamanqaku ahlukeneyo ngexesha!Nokuba ukrola isiqwenga esinye ngexesha okanye itafile egcwele amacandelo, kunye nenkqubo yokuseta lula kunye nobuchule bokuphawula obuchanekileyo, i-laser yefiber lukhetho olufanelekileyo lokukrolwa kwebhakhowudi yesiko.

Ngomatshini wokwenza ifayibha, unokukrola phantse kuyo nayiphi na intsimbi.kubandakanywa insimbi engenasici, isixhobo somatshini wensimbi, ubhedu, i-carbon fiber, kunye nokunye.

Ityala lefowuni

Njengoko ifowuni ephathwayo iya isiba krelekrele ngakumbi, ikhaphukhaphu kwaye incinci, iziphene zetekhnoloji yokuvelisa itekhnoloji yemveli ziyandiswa ngokuqhubekayo, kwaye itekhnoloji ye-laser laser yokukrola itekhnoloji iye yangeniswa ngempumelelo kwishishini lokwenziwa kweefowuni eziphathwayo, kwaye iye yakhawuleza ukuba yintandane. ishishini lokwenziwa kweemfonomfono.Xa kuthelekiswa nokusetyenzwa kwe-inkjet yemveli, i-laser laser engraving ineenzuzo zokuchaneka okuphezulu, ukunganxibelelani, okusisigxina, ukuchasana nomgunyathi kunye nokusebenza kakuhle okuphezulu.

Ulwazi lwemveliso, inombolo yelungelo lomenzi kunye nezinye iifonti zolwazi kwiqokobhe elingasemva lefowuni ephathwayo zincinci kakhulu.Ubugcisa bendabuko bunokuhlangabezana neemfuno zabalinganiswa abancinci, kwaye umatshini wokumakisha we-laser unendawo encinci yokugxila.Ngokweemfuno ezahlukeneyo, ubuncinci uphawu lunokuba yi-0.1mm.Ngezantsi, ulungele ngokupheleleyo iimfuno ezintsha.Ukuphuhliswa kwee-casings zefowuni eziphathwayo kuye kwafumana iiplastiki, i-anode aluminiyam, i-ceramics, iqokobhe lepeyinti yesinyithi, iglasi kunye nezinye izinto.Iindidi ezahlukeneyo zoomatshini bokuphawula i-laser zisetyenziswa kwizinto ezahlukeneyo.Ngokomzekelo, iiplastiki zisebenzisa i-laser ye-UV ultraviolet, ngelixa i-anode aluminiyam kunye neekeramics Umatshini wokumakisha we-fiber laser we-pulsed fibre wasetyenziswa, kunye nokumakishwa kweglasi kwazanywa ekuqaleni, kodwa ekugqibeleni kwashiywa.

Izinto eziluncedo kwitekhnoloji ye-laser yokukrola itekhnoloji kwi-casing yefowuni ephathwayo: I-laser laser engraving processing ithembekile kakhulu.Imizobo ephawulweyo, iimpawu, iinombolo zesiriyali, ezicacileyo nezingagugiyo, azinakuqhagamshelwana nazo, ngoko ke i-workpiece esetyenzisiweyo ayonakaliswa okanye ikhubazeke.Umzobo wekhompyutha welaser welaser, useto lokubhala, lwenzululwazi.Ilogo efunekayo inokuskenwa ngokwe logo ebonelelwe ngumthengi;inombolo yothotho i-auto-coded ngokupheleleyo.

Ukongeza, ukukrolwa kwelaser laser kunomsebenzi oqinileyo wokuchasana nomgunyathi.Yenza iimveliso zakho zingabi sesichengeni somgunyathi, kwiimpahla zokwenyani, kwaye kufuneka zidume ngakumbi.Isantya sokukrola sikhawuleza kwaye ixesha lomelele, eliphucula ukusebenza kakuhle kwemveliso.Umkrolo weLaser laser ulungile, umhle kwaye unoxabiso olomeleleyo.Ukumakishwa kunokuchaneka kokumakisha okuphezulu, inkangeleko entle, inkangeleko enesisa kunye nesiphumo esihle sokujonga.

Ifenitshala

Kwiminyaka yakutshanje, kumzi-mveliso wefenitshala, itekhnoloji ye-laser isetyenziselwe ukusika kunye nokukrola, okuye kwafumana iziphumo ezilungileyo kunye nokuphucula umgangatho kunye nokusebenza kakuhle kokwenziwa kwefenitshala.

Kukho iindlela ezimbini zokusebenza ngeteknoloji ye-laser kwinkqubo yokwenziwa kwefenitshala: ukukrola kunye nokusika.Indlela yokukrola ifana ne-embossing, oko kukuthi, ukusetyenzwa okungangeni.Ukukrola iipateni kunye nesicatshulwa.Imizobo enxulumeneyo inokucutshungulwa ngekhompyuter isiqingatha semi-processing ye-dimensional-dimensional, kwaye ubunzulu bomkrolo bunokufikelela ngokubanzi kwi-3 mm.

Ukusika kweLaser kusetyenziswa kakhulu ekwenzeni ifenitshala yokusika i-veneer.Ifenitshala ye-MDF ye-veneer iyona nto iphambili yefenitshala yangoku ephezulu, kungakhathaliseki ukuba ifenitshala ye-neo-classical okanye ifenitshala yepaneli yanamhlanje usebenzisa imveliso ye-MDF ye-veneer yindlela yokuphuhlisa.Ngoku ukusetyenziswa kwe-veneer inlays yemibala eyahlukeneyo kunye nemibala ekuveliseni ifenitshala ye-neo-classical ivelise ifenitshala eyenzelwe ngokucokisekileyo, eye yaphucula incasa yefenitshala, kwaye yandisa umxholo wezobugcisa wefenitshala kunye nokwandisa inzuzo.indawo.Kwixesha elidlulileyo, ukusika kwe-veneer kwabonwa ngesandla ngesarha yocingo, eyayichitha ixesha kunye nomsebenzi onzima, kwaye umgangatho wawungaqinisekiswanga, kwaye ixabiso liphezulu.Ukusetyenziswa kwe-laser-cut veneer kulula, kungekhona nje ukuphindaphinda i-ergonomics, kodwa nangenxa yokuba ububanzi be-laser beam bufikelela kwi-0.1 mm kunye nobubanzi bokusika emthini kuphela malunga ne-0.2 mm, ngoko ke iphethini yokusika ayinakulinganiswa.Emva koko ngenkqubo ye-jigsaw, i-paste, polishing, painting, njl., Yakha iphethini elihle phezu kwefenitshala.

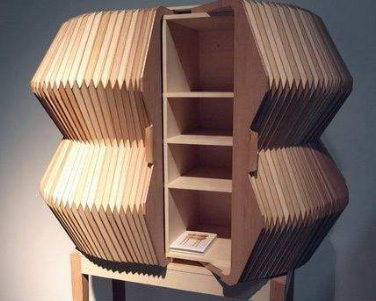

Le "ikhabhinethi ye-accordion", umaleko wangaphandle wekhabhinethi uhlanganiswe njenge-accordion.Iitshiphusi zokhuni ezisikwe nge-laser zincanyathiselwe ngesandla kumphezulu welaphu elinjengeLycra.Ukudityaniswa kobuchule kwezi zinto zimbini kwenza umphezulu weplanga uthambe kwaye ulastiki njengelaphu.Isikhumba esifana ne-accordion sivala ikhabhinethi yoxande, enokuthi ivalwe njengomnyango xa ingasetyenziswa.

Ileyibhile die cutter

Itekhnoloji eyayingaphandle kushishino loshicilelo lweleyibhile yewebhu kungekudala kudala iyaqhubeka ibona ukunyuka kokufaneleka.Ukusika kweLaser die kuye kwavela njengokhetho olusebenzayo lokugqiba kubaguquli abaninzi, ngakumbi ngokuxhaphaka koshicilelo olufutshane lwedijithali.

Iflegi yesibhengezo

Njengesixhobo sokubonisa esigqwesileyo, iiflegi zentengiso zisetyenziswa ngakumbi nangakumbi kwimisebenzi eyahlukeneyo yentengiso yentengiso.Kwaye iintlobo zeebhena zikwahluka, iiflegi zenaliti yamanzi, iflegi yolwandle, iflegi yenkampani, iflegi ye-antique, i-bunting, iflegi yomtya, iflegi yeentsiba, iflegi yesipho, iflegi ejingayo njalo njalo.

Njengoko iimfuno zorhwebo ziba zezenu, iintlobo ezilungiselelweyo zeeflegi zentengiso ziye zanda.Utshintshiselwano oluphezulu lwe-thermal kunye neteknoloji yoshicilelo lwedijithali kwiintengiso zesibhengezo zentengiso zihamba phambili, kodwa ukungahambelani kuseyinto yakudala kakhulu.

Oomatshini bethu bahle kakhulu ekusikeni ubukhulu obahlukeneyo kunye neflegi yefreyimu ngokwezicelo zabathengi.Inceda ukunciphisa imveliso kunye nabasebenzi kumashishini emveli, ukuphucula imveliso yabasebenzi kunye nezinga lomgangatho wemveliso.

Ikhaphethi

Ikhaphethi esetyenziswa ngokubanzi kwiindawo zokuhlala, iihotele, amabala emidlalo, iiholo zemiboniso, izithuthi, iinqanawa, iinqwelomoya kunye nezinye izigqubuthelo zomgangatho, kukho ukucutha ingxolo, ukugqunywa kwe-thermal kunye nefuthe lokuhombisa.

Ikhaphethi yesiNtu isetyenziswa ngokubanzi ukusikwa ngesandla, ukusikwa kombane okanye ukusika iDie.Isantya sokusika sabasebenzi sihamba kancinci, ukuchaneka kokusikwa akunakuqinisekiswa, kudla ngokufuna ukusika okwesibini, kunenkunkuma eninzi;sebenzisa ukusika kombane, isantya sokusika siyakhawuleza, kodwa kwiikona zokusika iigraphics ezintsonkothileyo, ngenxa yezithintelo ngokugoba kwegophe, zihlala zineziphene okanye azinakunqunyulwa, kwaye ngokulula zineendevu.Ukusebenzisa ukusika ukufa, kufuneka wenze isikhunta ekuqaleni, nangona isantya sokusika sikhawuleza, ngenxa yombono omtsha, kufuneka senze isikhunta esitsha, sasineendleko eziphezulu zokwenza i-mold, umjikelezo omde, iindleko eziphezulu zokugcina.

Ukusika kweLaser kukusetyenzwa kwe-thermal engadibanisiyo, abathengi balayisha kuphela ikhaphethi kwiqonga lokusebenza, inkqubo ye-laser iya kusika ngokwepateni eyiliweyo, iimilo ezinzima ngakumbi zinokusikwa ngokulula.Kwiimeko ezininzi, ukusika i-laser yeekhaphethi zokwenziwa phantse akukho cala liphekiweyo, umphetho unokutywina ngokuzenzekelayo, ukunqanda ingxaki yeendevu.Abathengi abaninzi basebenzise umatshini wethu wokusika i-laser ukusika ikhaphethi yeemoto, inqwelomoya, kunye nekhaphethi yokusika i-doormat, bonke baye baxhamla koku.Ukongeza, ukusetyenziswa kobuchwephesha belaser kuye kwavula iindidi ezintsha kushishino lweekhaphethi, ezizezi, ikhaphethi ekroliweyo kunye nekhaphethi yokufaka inlay, iimveliso ezahluliweyo zekhaphethi ziye zaba zezona mveliso ziphambili, zamkelwa kakuhle ngabathengi.(Ilaser yegolide)

Iimoto zangaphakathi

Kwindawo yangaphakathi yeemoto (ikakhulukazi izihlalo zokuhlala zemoto, iikhaphethi zeemoto, i-airbags, njl.) Iindawo zokuvelisa, ngokukodwa ukuveliswa kwe-cushion yemoto, eyona ndlela yokusika i-computer kunye nokusika ngesandla.Njengoko ixabiso lebhedi yokusika ikhompyuter liphezulu kakhulu (elona xabiso liphantsi lingaphezulu kwe-1 yezigidi zeeYuan), lingaphezulu kakhulu kumandla okuthenga ngokubanzi amashishini okuvelisa, kwaye kunzima ukusika umntu, ngoko ke iinkampani ezininzi zisasebenzisa ukusika ngesandla.Kodwa umatshini weAeon laser lukhetho olukhulu.

Emva kokusetyenziswa kwe-AEON laser cutting machine, ixesha lomatshini wokusika isethi yezihlalo liyancitshiswa libe yimizuzu engama-20.Njengoko ukusetyenziswa kwenkqubo yokucwangcisa ngobuchule, ilahleko yezinto eziphathekayo nayo iyancipha kakhulu, kwaye iphelisa iindleko zomsebenzi wokusika ngesandla, ngoko ke iindleko ziyancipha kakhulu.Idityaniswe nokusetyenziswa kwenkqubo yokondla ngokuzenzekelayo, okwenza ukuba ukusebenza kwemveliso kunyuke ngesinye kwisithathu.Ngelixa inguqu yesofthiwe ifakwe, yenza inguqu yenguqu elula yokutshintsha, isakhiwo semveliso siye satyetyiswa kakhulu, iimveliso ezintsha zivela kumlambo ongapheliyo;Kule nkqubo, ukusika i-laser, ukugrumba, ukukrola kunye nokunye ukudityaniswa kwetekhnoloji entsha eyandisa kakhulu imveliso yexabiso elongeziweyo, kwaye ikhokele itekhnoloji yokulungiswa kwangaphakathi kweemoto zefashoni entsha, ukuvuselelwa ngokukhawuleza kwamashishini.

Imidiya yokuhluza

Ukuhluzwa yinkqubo ebalulekileyo yolawulo lokusingqongileyo kunye nokhuseleko.Ukusuka kwi-industrial gas-solid-solid, ukuhlukana kwe-gas-liquid, ukuhlukana okuqinileyo, ukuhlukana okuqinileyo, ukuhlanjululwa komoya wemihla ngemihla kunye nokuhlanjululwa kwamanzi kwezixhobo zendlu, ukucoca kuye kwanda kakhulu.Faka isicelo kwimimandla emininzi.Izicelo ezikhethekileyo ezifana nezityalo zamandla, iintsimbi zetsimbi, izityalo zesamente, njl., i-textile kunye neshishini leengubo, ukuhluzwa komoya, ukucocwa kwamanzi amdaka, ukuhluzwa kweekhemikhali kunye ne-crystallization, i-automotive industry air, i-oil filters kunye ne-air conditioners yasekhaya, i-vacuum cleaners, njl.

Ezona zixhobo zokucoca zizixhobo zefayibha, amalaphu alukiweyo kunye nemathiriyeli yentsimbi, ngakumbi ezona zixhobo zisetyenziswa kakhulu kwifayibha, ikakhulu umqhaphu, uboya, ilinen, isilika, iviscose, ipolypropylene, inayiloni, ipolyester, iacrylic, nitrile, ifayibha zokwenziwa, njl.Kwaye i-glass fiber, i-ceramic fiber, i-fiber yensimbi, kunye nokunye okunjalo.

Oomatshini bokusika i-Laser bakhawuleza kwaye basebenza kakuhle kuneendlela zendabuko.Inokusika naluphi na uhlobo lweemilo ngaxeshanye.Inyathelo elinye kuphela lokuyifezekisa kwaye akukho mfuneko yokuphinda usebenze.Oomatshini abatsha bayakunceda wonge ixesha, wonge imathiriyeli kwaye wonge indawo!

Ukusika iPlywood

Ngomatshini wokusika we-AEON kunye nokuzibandakanya, kuya kwenza inkqubo yakho yokusebenza ibe lula kwaye ikhawuleze.Ngoncedo lomatshini omnye kuphela we-Aeon, unokwenza ukusika, ukukrola okanye ukuphawula kwiplanga kwelinye icala ngaphandle koncedo lwabanye oomatshini.

Ukusika iinkuni kunye nokukrola zimbini zezona zicelo zidumileyo zelaser kuba zinokubandakanya iiprojekthi ezininzi ezahlukeneyo.Ukusuka kwikhabhinethi ukuya kwiifreyimu zeefoto ukuya kwiziphatho zemela, iinkqubo ze-AEON Laser zisetyenziswa phantse kulo lonke udidi lwamaplanga oya kuwela kulo.Nokuba usebenza ngamaplanga aqinileyo, iiveneers, inlays, mdf, plywood, walnut, alder, okanye icherry, unokukrola imifanekiso entsonkothileyo emangalisayo ngenkqubo yelaser.

Ukusika amashidi enkuni kwiimilo ezahlukeneyo kunye nobude obuhlukeneyo sisiqwenga nje sekhekhe ngoncedo lomatshini wethu wokusika we-laser.Uyilo lwethu olukhethekileyo lokugqitha kumnyango luya kukunceda ukuba ujongane nezixhobo ezinde zesidlo sangokuhlwa.unokusika ubude obungenamkhawulo bomthi nangaphandle komatshini omkhulu.

Xa ufuna ukongeza ezinye izinto zokuhombisa kwiimveliso zakho zomthi ezifana nesakhelo sefoto yomthi, ibhokisi yomthi, ikama yomthi okanye iingcango zomthi, umsiki wethu we-laser we-AEON uya kuguqukela kumatshini wokukrola we-laser ukuze akuncede.Kulula kakhulu kwaye kulula ukukrola iilogo zakho, imifanekiso yakho kunye nezicatshulwa kwiimveliso zakho zomthi ngokusebenzisa umatshini wokukrola we-laser we-AEON.

Ngombulelo kumatshini we-laser, akuyomfuneko ukuba uhlukanise umkrolo womthi we-laser kunye nokusika kwe-laser yamaplanga kubini.ngoku ungayenza le misebenzi mibini yahlukeneyo ngexesha elinye!Kwakhona ukukrola i-3D kunokufezekiswa ngoku!

Amagwebu

Umatshini we-laser we-AEON ufanelekile kakhulu ukusika izinto ze-foam.Njengoko inqumla ngendlela engabonakaliyo, ngoko akuyi kuba nomonakalo okanye ukuguqulwa kwi-foam.Kwaye ubushushu be-co2 laser buya kutywina umda xa usikwa kwaye ukrolwa ukuze umphetho ucoceke kwaye ugudileyo ekunganyanzelekanga ukuba uphinde uwusebenzise.Ngesiphumo sayo esihle kakhulu sokusika i-foam, umatshini we-laser usetyenziswa ngokubanzi ukusika i-foam kwisicelo esithile sobugcisa.

Iifoam ezenziwe nge-polyester (PES), i-polyethylene (PE) okanye i-polyurethane (i-PUR) ifaneleke kakuhle ukusika i-laser, i-laser engraving.I-Foam isetyenziselwa ukufaka i-suitcase okanye i-padding, kunye ne-seals.Ngaphandle kwezi, i-laser cut foam iphinda isetyenziswe kwizicelo zobugcisa, njengezikhumbuzo okanye iifreyimu zeefoto, umzekelo.

I-laser sisixhobo esibhetyebhetye kakhulu: Yonke into inokwenzeka, ukusuka kulwakhiwo lweprototype ukuya kwimveliso yothotho.Unokusebenza ngokuthe ngqo kwiprogram yoyilo, ebaluleke kakhulu ngokukodwa kwindawo yeprototyping ngokukhawuleza.Xa kuthelekiswa nenkqubo yokusika ijethi yamanzi entsonkothileyo, i-laser ikhawuleza kakhulu, iguquguquka ngakumbi kwaye isebenza kakuhle.Ukusika i-Foam ngomatshini we-laser kuya kuvelisa imiphetho ecocekileyo netywiniweyo.

Ibhodi yombala kabini ABS

ABS umbala kabini ibhodi luhlobo ABS sheet.Isetyenziswa kakhulu kwiimarike.Ikwafumaneka kwiindidi ezininzi.Inokwahlulwa ibe ziindidi ezimbini: umbala ogcweleyo webhodi enemibala emibini, ibhodi yesinyithi-engaphezulu kwemibala emibini kunye nebhodi yezandla enemibala emibini.

I-ABS--AEON Laser -i-mira series ingafaka isicelo sokusika uMbala oMbini we-ABS ngesantya esikhawulezayo sokusika kunye nesiphumo esihle kakhulu sokusika.Ngokuqinisekileyo, umgangatho wokusika ubukhulu becala uxhomekeke kumandla okusika kunye nesantya.

Iinkqubo zokusika i-Laser zinokusika iindidi ezininzi ze-ABS zobunzima obuhlukeneyo kwaye zifaneleke ngokufanelekileyo ukudala iimilo ezinzima.Isiphumo sokukrola kumbala ophindwe kabini we-ABS nawo ukumgangatho ophezulu.Abathengi abaninzi bathanda ukuyisebenzisela ukukrola oonobumba kunye neelogo kwiipleyiti zamagama ze-ABS kunye noMbala oMbini.Xa kuthelekiswa neendlela zemveli, ukusika kwe-laser kunye nokukrola kuguquguquka ngakumbi, ngokukhawuleza, kusebenza kakuhle kwaye kuchaneke ngakumbi.