Ubucwebe

Lapho kwenziwa ubucwebe, sekusetshenziswa izinto eziningi ezihlukene, ikakhulukazi izinsimbi eziyigugu nama-alloys.Ngokwesiko, imboni isebenzise izindlela eziningi ezifana nokuqopha (ukukhiqiza ngomshini) noma ukunamathisela.Esikhathini esidlule, isizathu esibalulekile sokwenza izimbobo zegolide emisebenzini ebizayo kwakuwukwenza kube ngokwakho noma ukwengeza imibhalo ebhaliwe enengqondo.Namuhla, umklamo wokudala wobucwebe, kuhlanganise nensimu yobucwebe bemfashini, uba ngobaluleke kakhulu.Ngobuchwepheshe be-laser, izinsimbi eziyigugu ezifana nezinsimbi ze-laser nazo zonke ezinye izinsimbi zingasetshenziswa.

Ngezansi kunezinzuzo ezimbalwa zemishini yokusika i-laser uma kuqhathaniswa nezindlela zokusika zendabuko:

Ukuhlanekezela okuncane ezingxenyeni ngenxa yendawo encane ethintekile ekushiseni

Ukusika ingxenye eyinkimbinkimbi

Ububanzi be-kerf obuncane

Ukuphindaphinda okuphezulu kakhulu

Ngesistimu yokusika i-laser ungakha kalula amaphethini wokusika ayinkimbinkimbi wemiklamo yakho yobucwebe:

I-interlocking monograms

I-Circle Monograms

Yisho Imigexo

Complex Custom Designs

Ama-pendants nezintelezi

Amaphethini Ayinkimbinkimbi

Izingxenye Zangokwezifiso Zodwa Zohlobo

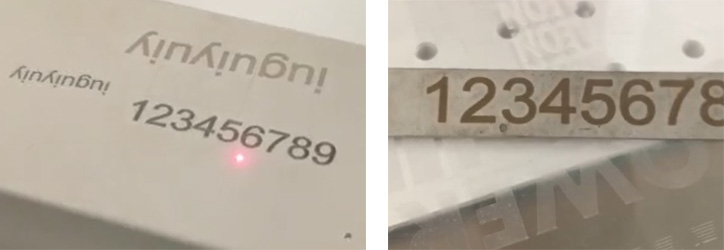

Ibhakhodi

I-Laser iqopha amakhodi akho ebha, izinombolo ze-serial, namalogo ngohlelo lwe-AEON Laser.Amakhodi olayini nawe-2D, njengezinombolo ze-serial, asevele esetshenziswa ezimbonini eziningi, ezifana (isb. imboni yezimoto, ubuchwepheshe bezokwelapha, noma imboni yezogesi), ukuze kwenziwe imikhiqizo noma izingxenye ngazinye zilandeleke.Amakhodi (ikakhulukazi i-matrix yedatha noma amakhodi ebha) aqukethe ulwazi mayelana nezakhiwo zezingxenye, idatha yokukhiqiza, izinombolo zeqoqo nokunye okuningi.Ukumakwa kwezingxenye ezinjalo kufanele kufundeke ngendlela elula futhi kancane nange-elekthronikhi futhi kube nokuqina okuhlala njalo.Lapha, ukumaka nge-laser kubonakala kuyithuluzi eliguquguqukayo nelisebenza emhlabeni wonke lezinhlobonhlobo zezinto, izimo nosayizi kanye nokucutshungulwa kwedatha eguquguqukayo neshintshayo.Izingxenye zimakwe nge-laser ngesivinini esiphezulu nokunemba okuphelele, kuyilapho ukugqokwa kuncane.

Amasistimu ethu e-fiber laser aqopha ngokuqondile noma aphawule noma iyiphi insimbi engenalutho noma eboshwe okuhlanganisa insimbi engagqwali, insimbi yamathuluzi, ithusi, i-titanium, i-aluminium nokunye okuningi, okukuvumela ukuthi udale izinhlobo zamamaki ezihlukahlukene ngokushesha!Kungakhathaliseki ukuthi uqopha ucezu olulodwa ngesikhathi noma ithebula eligcwele izingxenye, nenqubo yalo yokusetha elula namandla okumaka anembile, i-fiber laser iyinketho ekahle yokuqoshwa kwebhakhodi yangokwezifiso.

Ngomshini wokwenza i-fiber, ungaqopha cishe kunoma iyiphi insimbi.okuhlanganisa insimbi engagqwali, insimbi yethuluzi lomshini, ithusi, i-carbon fiber, nokunye.

Ikesi lefoni

Njengoba umakhalekhukhwini uya uba ngohlakaniphe kakhulu, ulula futhi uba mncane, amaphutha obuchwepheshe bokukhiqiza ubuchwepheshe bendabuko ayandiswa ngokuqhubekayo, kanye nobuchwepheshe bokucubungula i-laser laser engraving processing yethulwe ngempumelelo embonini yokukhiqiza amaselula, futhi ngokushesha isibe isithandwa sika. imboni yokukhiqiza omakhalekhukhwini.Uma kuqhathaniswa nokucutshungulwa kwe-inkjet yendabuko, ukuqoshwa kwe-laser kunezinzuzo zokunemba okuphezulu kokuqoshwa, okungathinteki, okuhlala njalo, ukulwa nokukhohlisa kanye nokusebenza kahle okuphezulu.

Ulwazi lokukhiqiza, inombolo yelungelo lobunikazi namanye amafonti olwazi kugobolondo elingemuva lefoni ephathekayo mancane kakhulu.Ubuciko bendabuko bungahlangabezana nezidingo zezinhlamvu ezincane, futhi umshini wokumaka we-laser unendawo encane yokugxila.Ngokwezidingo ezihlukene, uhlamvu oluncane lungaba ngu-0.1mm.Ngezansi, ufanelekele ngokugcwele izidingo ezintsha.Ukuthuthukiswa kwama-casings omakhalekhukhwini nakho kuhlangabezane namapulasitiki, i-anode aluminium, i-ceramics, amagobolondo kapende wensimbi, ingilazi nezinye izinto.Izinhlobo ezahlukene zemishini yokumaka laser isetshenziswa ezintweni ezahlukene.Isibonelo, amapulasitiki asebenzisa amalaser e-UV ultraviolet amaningi, kuyilapho i-anode aluminium kanye ne-ceramics Umshini wokumaka we-pulsed fiber laser wasetshenziswa, futhi ukumaka ingilazi kwazanywa ekuqaleni, kodwa kwagcina kuyekwa.

Izinzuzo ze-laser laser engraving processing technology ku-casing yocingo lweselula: I-laser engraving processing inokwethenjelwa kakhulu.Imifanekiso emakiwe, izinhlamvu, izinombolo ze-serial, ezicacile futhi azigugi, azicutshungulwa okuthintwayo, ngakho-ke ucezu olucutshungulwayo alonakali noma lonakale.Umdwebo wekhompyutha we-laser we-laser, ukuhlelwa kwe-typesetting, isayensi.Ilogo edingekayo ingaskenwa ngokuhambisana nelogo ehlinzekwe yikhasimende;inombolo ye-serial i-auto-coded ngokuphelele.

Ngaphezu kwalokho, ukuqoshwa kwe-laser laser kunokusebenza okuqinile kokulwa nomgunyathi.Yenza imikhiqizo yakho ingathinteki kalula ekwenziweni komgunyathi, izimpahla zangempela, futhi kumele idume kakhulu.Ijubane lokuqopha liyashesha futhi isikhathi sinamandla, okuthuthukisa ukusebenza kahle kokukhiqiza.Umdwebo we-laser we-laser muhle, muhle futhi unokwazisa okuqinile.Ukumaka kunokunemba okuphezulu kokumaka, ukubukeka okuhle, ukubukeka okuphanayo nomphumela omuhle wokubuka.

Ifenisha

Eminyakeni yamuva, embonini yokukhiqiza ifenisha, ubuchwepheshe be-laser buye basetshenziselwa ukusika nokuqopha, okuzuze imiphumela emihle futhi kwathuthukisa ikhwalithi nokusebenza kahle komsebenzi wokukhiqiza ifenisha.

Kunezindlela ezimbili zokusebenza ngobuchwepheshe be-laser ohlelweni lokukhiqiza ifenisha: ukuqopha nokusika.Indlela yokuqopha ifana ne-embossing, okungukuthi, ukucubungula okungangeni.Ukuqopha amaphethini nombhalo.Imifanekiso ehlobene ingacutshungulwa ngekhompuyutha ukuze icutshungulwe uhafu-ntathu, futhi ukujula kokuqoshwa ngokuvamile kungafinyelela ngaphezu kuka-3 mm.

Ukusika kwe-Laser kusetshenziswa ikakhulukazi ekwenzeni ifenisha yokusika i-veneer.Ifenisha ye-MDF ye-veneer iyinhloko yefenisha yamanje ephezulu, kungakhathaliseki ukuthi ifenisha ye-neo-classical noma ifenisha yamaphaneli yesimanje isebenzisa ukukhiqizwa kwe-MDF veneer kuwumkhuba wokuthuthukiswa.Manje ukusetshenziswa kwe-veneer inlays yemibala ehlukene kanye nokuthungwa ekukhiqizeni ifenisha ye-neo-classical kuye kwakhiqiza ifenisha eklanywe ngokuningiliziwe, eye yathuthukisa ukunambitheka kwefenisha, futhi yandisa okuqukethwe kwezobuchwepheshe kwefenisha kanye nenzuzo eyengeziwe.isikhala.Esikhathini esidlule, ukusika kwe-veneer kwakunqunywe ngesandla ngesaha locingo, okwakudla isikhathi futhi kusebenze kanzima, futhi ikhwalithi yayingaqinisekisiwe, futhi izindleko zaziphezulu.Ukusetshenziswa kwe-laser-cut veneer kulula, hhayi nje ukuphinda kabili i-ergonomics, kodwa futhi ngoba ububanzi be-laser beam bufika ku-0.1 mm futhi ububanzi bokusika okhuni bungaba ngu-0.2 mm kuphela, ngakho-ke iphethini yokusika ayinakuqhathaniswa.Khona-ke ngenqubo ye-jigsaw, unamathisele, ukupholisha, ukudweba, njll, yakha iphethini elihle ebusweni befenisha.

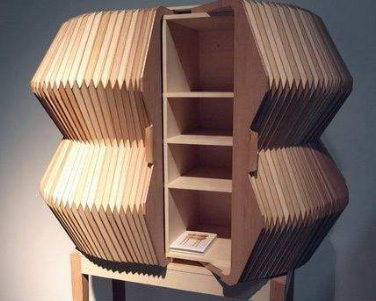

Lena "ikhabhinethi ye-accordion", ungqimba lwangaphandle lwekhabhinethi lugoqwe njenge-accordion.Ama-chips okhuni asikwe nge-laser anamathiselwe ngesandla ebusweni bendwangu efana ne-Lycra.Inhlanganisela ehlakaniphile yalezi zinto ezimbili yenza ingaphezulu lokhuni lithambe futhi linwebeka njengendwangu.Isikhumba esifana ne-accordion sivala ikhabethe elingunxande, elingavalwa njengomnyango uma lingasetshenziswa.

Ilebula i-die cutter

Ubuchwepheshe obabungaphandle embonini yokuphrinta ilebula yewebhu kungekudala buyaqhubeka nokubona ukukhuphuka kokuhambisana.Ukusika i-laser die sekuvele njengendlela esebenzayo yokuqeda iziguquli eziningi, ikakhulukazi ngokusabalala kokuphrinta kwedijithali okufushane.

Ifulegi lesibhengezo

Njengethuluzi elihle kakhulu lokubonisa, amafulegi okukhangisa asetshenziswa kakhulu emisebenzini ehlukahlukene yokukhangisa kwezentengiso.Futhi izinhlobo amabhanela nazo ezihlukahlukene, amafulege umjovo amanzi, ifulege beach, ifulege corporate, ifulege antique, bunting, string ifulege, feather flag, isipho flag, ukulengiswa flag nokunye.

Njengoba izimfuno zentengiso ziba ngezakho kakhulu, izinhlobo ezenziwe ngezifiso zamafulegi okukhangisa nazo zinyukile.Ukudlulisa okushisayo okuthuthukisiwe kanye nobuchwepheshe bokuphrinta bedijithali ezikhangisweni zesibhengezo sangokwezifiso buyakhona, kodwa ukungafani kusewukusikwa kwakudala kakhulu.

Imishini yethu inhle kakhulu ekusikeni usayizi ohlukile kanye nefulegi lozimele ngokusho kwezicelo zamakhasimende.Isiza ukunciphisa ukukhiqizwa kanye nokusebenza kwamabhizinisi endabuko, ukuthuthukisa ukukhiqizwa kwabasebenzi kanye nezinga lekhwalithi yomkhiqizo.

Ukhaphethi

Ukhaphethi osetshenziswa kabanzi ezindaweni zokuhlala, amahhotela, izinkundla, amahholo emibukiso, izimoto, imikhumbi, izindiza kanye nezinye izembozo zaphansi, kukhona ukuncishiswa komsindo, ukwahlukanisa okushisayo nomphumela wokuhlobisa.

Ukhaphethi wendabuko uvame ukusetshenziswa ukusika ngesandla, ukusika kukagesi noma i-Die cut.Ijubane lokusika labasebenzi lihamba kancane, ukunemba kokusika akunakuqinisekiswa, ngokuvamile kudinga ukusika okwesibili, kube nezinto eziningi zokulahla;sebenzisa ukusika kukagesi, isivinini sokusika siyashesha, kodwa emakhoneni okusika ihluzo eziyinkimbinkimbi, ngenxa yemikhawulo ngokugoba kwesibaya, ngokuvamile aneziphambeko noma azikwazi ukunqunywa, futhi kalula abe nentshebe.Ukusebenzisa i- die cutting , idinga ukwenza isikhunta ekuqaleni, nakuba ijubane lokusika liyashesha, ngombono omusha, kufanele lenze isikhunta esisha, sasinezindleko eziphakeme zokwenza isikhunta, umjikelezo omude, izindleko eziphezulu zokugcinwa.

Ukusika i-Laser kuwukucutshungulwa okushisayo okungathinteki, amakhasimende avele alayishe umata endaweni yokusebenza, uhlelo lwe-laser luzobe lusika ngokwephethini eklanyelwe, ukubunjwa okuyinkimbinkimbi kungasikwa kalula.Ezimweni eziningi, i-laser cutting for synthetic carpets yayingenalo cishe uhlangothi oluphekiwe, unqenqema lungavala ngokuzenzakalelayo, ukugwema inkinga yentshebe emaphethelweni.Amakhasimende amaningi asebenzise umshini wethu wokusika i-laser ukusika ukhaphethi wezimoto, izindiza, kanye nokhaphethi wokusika umata womnyango, bonke bazuze kulokhu.Ukwengeza, ukusetshenziswa kobuchwepheshe be-laser kuye kwavula imikhakha emisha embonini yokhaphethi, okuwukuthi ukhaphethi oqoshiwe kanye nokufakwa kukakhaphethi, imikhiqizo ehlukene kakhaphethi isiyimikhiqizo ethandwa kakhulu, yamukelwa kahle ngabathengi.(I-laser yegolide)

Ingaphakathi lemoto

Ngaphakathi kwezimoto (ikakhulukazi izembozo zezihlalo zemoto, amakhaphethi, ama-airbags, njll.) izindawo zokukhiqiza, ikakhulukazi ukukhiqizwa kwe-cushion yemoto, indlela eyinhloko yokusika yokusika ikhompyutha nokusika ngesandla.Njengoba intengo yombhede wokusika ikhompiyutha iphezulu kakhulu (intengo ephansi ingaphezu kwe-1 million Yuan), ingaphezu kwamandla okuthenga ajwayelekile amabhizinisi okukhiqiza, futhi kunzima ukusika umuntu uqobo, ngakho izinkampani eziningi zisasebenzisa ukusika ngesandla.Kodwa umshini we-laser we-Aeon uyisinqumo esihle.

Ngemuva kokusetshenziswa komshini wokusika i-AEON laser, isikhathi somshini wokusika isethi yezihlalo sincishiswa sibe yimizuzu engama-20.Njengokusetshenziswa kwesistimu yokuhlela ehlakaniphile, ukulahlekelwa kwempahla nakho kuncipha kakhulu, futhi kuqeda izindleko zomsebenzi owenziwe ngesandla, ngakho-ke izindleko zehla kakhulu.Kuhambisana nokusetshenziswa kwesistimu yokudla okuzenzakalelayo, okwenza ukusebenza kahle kokukhiqiza kukhule ngengxenye eyodwa kwezintathu.Ngenkathi inguqulo yesofthiwe ishumekiwe, yenza inguqulo yenguqulo elula yokuguqula, isakhiwo somkhiqizo sithuthukiswe kakhulu, imikhiqizo emisha ivela emfudlaneni ongapheli;Kule nqubo, ukusika kwe-laser, ukumba, ukuqopha nokunye ukuhlanganiswa kobuchwepheshe obusha okwandise kakhulu imikhiqizo ye-value-added, futhi kuholele ekucubunguleni ingaphakathi lezimoto ubuchwepheshe bemfashini entsha, ukuvuselelwa kabusha okusheshayo kwamabhizinisi.

Imidiya yokuhlunga

Ukuhlunga kuyinqubo ebalulekile yokulawula imvelo nokuphepha.Kusukela ekuhlukaniseni igesi-okuqinile kwezimboni, ukuhlukaniswa kwe-gas-liquid, ukuhlukaniswa koketshezi oluqinile, ukuhlukaniswa okuqinile, ukuhlanzwa komoya nsuku zonke kanye nokuhlanzwa kwamanzi kwemishini yasendlini, ukuhlunga kuye kwanda kakhulu.Faka isicelo ezifundeni eziningi.Izinhlelo zokusebenza eziqondile ezifana nezitshalo zamandla, izigayo zensimbi, izitshalo zikasimende, njll., imboni yendwangu nezingubo, ukuhlunga komoya, ukuhlanza indle, ukuhluzwa kwamakhemikhali nokucwebezela, umoya wemboni yezimoto, izihlungi zikawoyela nezipholile zasendlini, izihlanzi ze-vacuum, njll.

Izinto zokuhlunga eziyinhloko ziyizinto ze-fiber, izindwangu ezilukiwe kanye nezinto zensimbi, ikakhulukazi izinto ze-fiber ezisetshenziswa kakhulu, ikakhulukazi ukotini, uboya, ilineni, usilika, i-viscose, i-polypropylene, inayiloni, i-polyester, i-acrylic, i-nitrile, i-synthetic fiber, njll.Futhi i-glass fiber, i-ceramic fiber, i-metal fiber, nokunye okunjalo.

Imishini yokusika i-laser iyashesha futhi isebenza kahle kunezindlela zendabuko.Ingakwazi ukusika noma yiziphi izinhlobo zomumo kanyekanye.Isinyathelo esisodwa kuphela sokuyifinyelela futhi asikho isidingo sokusebenza kabusha.Imishini emisha ikusiza ukuthi wonge isikhathi, wonge izinto zokwakha futhi wonge isikhala!

Ukusika i-plywood

Ngomshini wokusika we-AEON nohehayo, uzokwenza inqubo yakho yokusebenza ibe lula futhi isheshe.Ngosizo lomshini owodwa kuphela we-Aeon, ungenza ukusika, ukuqopha noma ukumaka ngokhuni ngokuphenduka okukodwa ngaphandle kosizo lweminye imishini.

Ukusika izinkuni nokuqoshwa yizinhlelo ezimbili ezidume kakhulu ze-laser ngoba zingahlanganisa amaphrojekthi amaningi ahlukene.Kusukela ku-cabinetry kuya kumafreyimu ezithombe kuya kuzibambo zommese, amasistimu we-AEON Laser asetshenziswa cishe kuzo zonke izigaba zamapulangwe ozodlula kuzo.Kungakhathaliseki ukuthi usebenza ngamapulangwe aqinile, ama-veneers, ama-inlay, i-mdf, i-plywood, i-walnut, i-alder, noma i-cherry, ungaqopha izithombe eziyinkimbinkimbi ngokumangalisayo ngesistimu ye-laser.

Ukusika amashidi ezinkuni abe yizimo ezahlukene kanye nobude obuhlukile kumane nje kuyisiqephu sekhekhe ngosizo lomshini wethu wokusika we-laser.Umklamo wethu okhethekile wokudlula emnyango uzokusiza ukuthi ubhekane nezinto ezinde zesidlo sakusihlwa.ungakwazi ukusika ubude obungenamkhawulo wezinkuni ngisho nangaphandle komshini omkhulu.

Uma udinga ukwengeza imihlobiso emikhiqizweni yakho yokhuni njengohlaka lwesithombe sokhuni, ibhokisi lezinkuni, ikamu lokhuni noma iminyango yokhuni, umsiki wethu we-laser we-AEON uzophendukela emshinini wokuqopha we-laser wokhuni ukukusiza.Kulula kakhulu futhi kulula ukuqopha amalogo akho, izithombe zakho siqu nemibhalo emikhiqizweni yakho yokhuni ngokusebenzisa umshini wokuqopha we-laser we-AEON.

Ngenxa yomshini we-laser, awudingi ukuhlukanisa ukuqoshwa kwezinkuni ze-laser nokusika i-laser yokhuni zibe izingxenye ezimbili.manje ungenza le misebenzi emibili ehlukene ngesikhathi esisodwa!Futhi ukuqopha i-3D kungafinyelelwa manje!

Amagwebu

Umshini we-laser we-AEON ulungele kakhulu ukusika izinto zegwebu.Njengoba isika ngendlela engathinteki, ngakho-ke ngeke kube nomonakalo noma ukuguqulwa kugwebu.Futhi ukushisa kwe-co2 laser kuzovala unqenqema lapho usikwa futhi uqoshwa ukuze unqenqema luhlanzeke futhi lubushelelezi okungadingeki ukuthi ulucubungule kabusha.Ngomphumela wawo omuhle kakhulu wokusika igwebu, umshini we-laser usetshenziswa kabanzi ukusika igwebu kwezinye izinhlelo zokusebenza zobuciko.

Amagwebu enziwe nge-polyester (PES), i-polyethylene (PE) noma i-polyurethane (i-PUR) ifaneleka kahle ukusika kwe-laser, ukuqoshwa kwe-laser.Igwebu lisetshenziselwa ukufaka ipotimende noma ukupheda, kanye nezimpawu.Ngaphandle kwalokhu, i-laser cut foam isetshenziselwa izinhlelo zokusebenza zobuciko, njengezikhumbuzo noma ozimele bezithombe, isibonelo.

I-laser iyithuluzi elivumelana nezimo kakhulu: Konke kuyenzeka, kusukela ekwakhiweni kwe-prototype kuya ekukhiqizeni okuwuchungechunge.Ungakwazi ukusebenza ngokuqondile ohlelweni lokuklama, olubaluleke kakhulu ikakhulukazi endaweni ye-prototyping esheshayo.Uma kuqhathaniswa nenqubo yokusika i-jet yamanzi eyinkimbinkimbi, i-laser ishesha kakhulu, iguquguquka futhi isebenza kahle.Ukusika igwebu ngomshini we-laser kuzokhiqiza imiphetho ehlanganiswe ngokuhlanzekile futhi evalwe uphawu.

Double color board ABS

I-ABS double color board iwuhlobo lweshidi le-ABS.Isetshenziswa kabanzi emakethe.Iyatholakala nangezinhlobo eziningi.Ingahlukaniswa ngezinhlobo ezimbili: ibhodi elinemibala emibili elinemibala egcwele, ibhodi lensimbi-engaphezulu elinemibala emibili kanye nebhodi lezandla lemibala emibili.

Uchungechunge lwe-ABS--AEON Laser -mira lungasebenza ukusika Umbala Ophindwe Kabili we-ABS ngesivinini sokusika esisheshayo nomphumela omuhle kakhulu wokusika.Yiqiniso, izinga lokusika lincike kakhulu emandleni okusika kanye nesivinini.

Amasistimu wokusika we-laser angasika izinhlobo eziningi ze-ABS zogqinsi oluhlukahlukene futhi afaneleka kahle ekudaleni izimo eziyinkimbinkimbi.Umphumela wokuqoshwa ku-double color ABS nawo usezingeni eliphezulu.Amakhasimende amaningi athanda ukuyisebenzisela ukuqopha izinhlamvu namalogo kumapuleti egama le-Double Color ABS nezimpawu.Uma kuqhathaniswa nezindlela zendabuko, ukusika nokuqoshwa kwe-laser kuvumelana nezimo, kuyashesha, kusebenza kahle futhi kunembe kakhudlwana.