Graveur et découpeur laser AEON NOVA10

Avantages du NOVA10

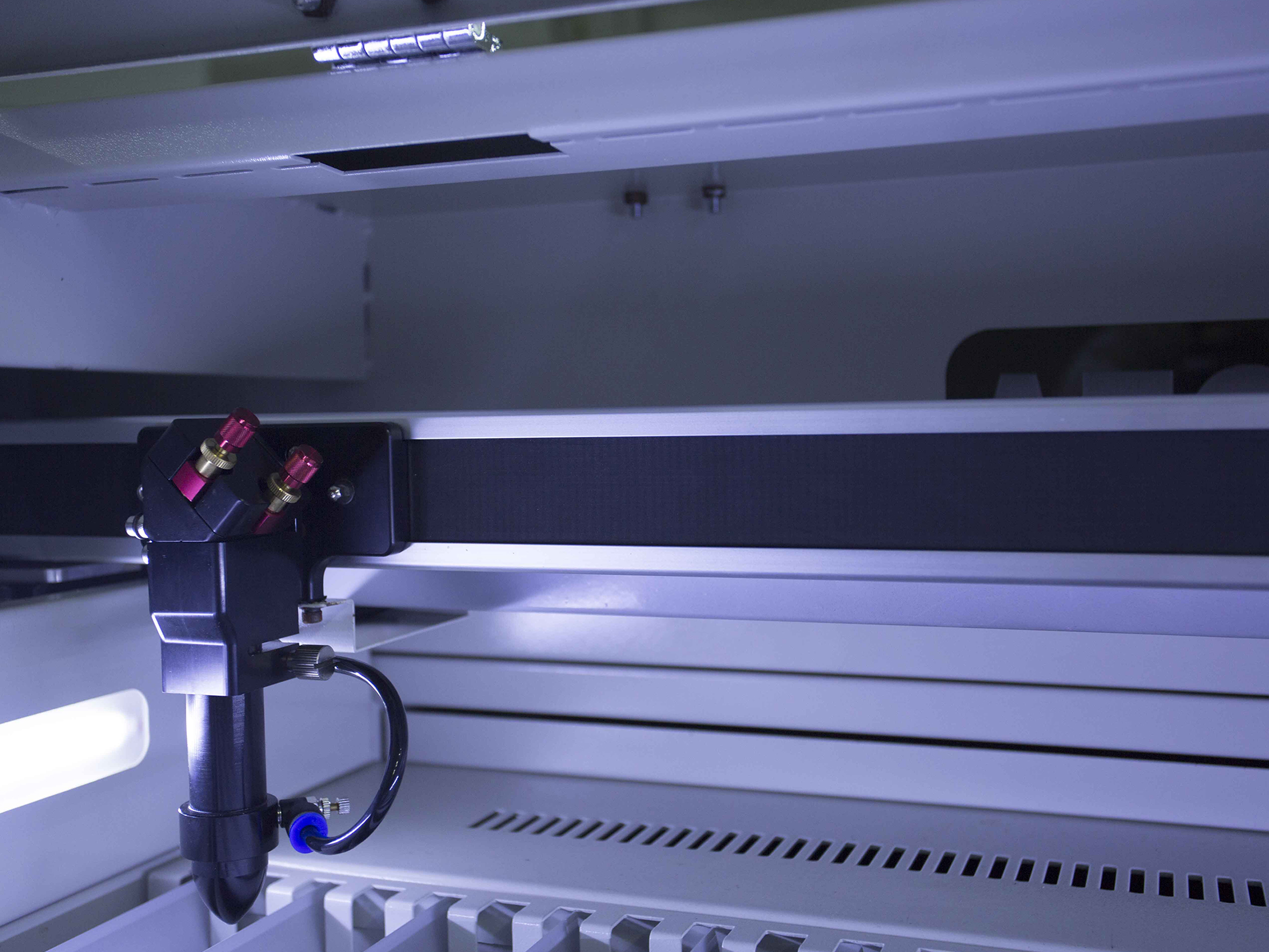

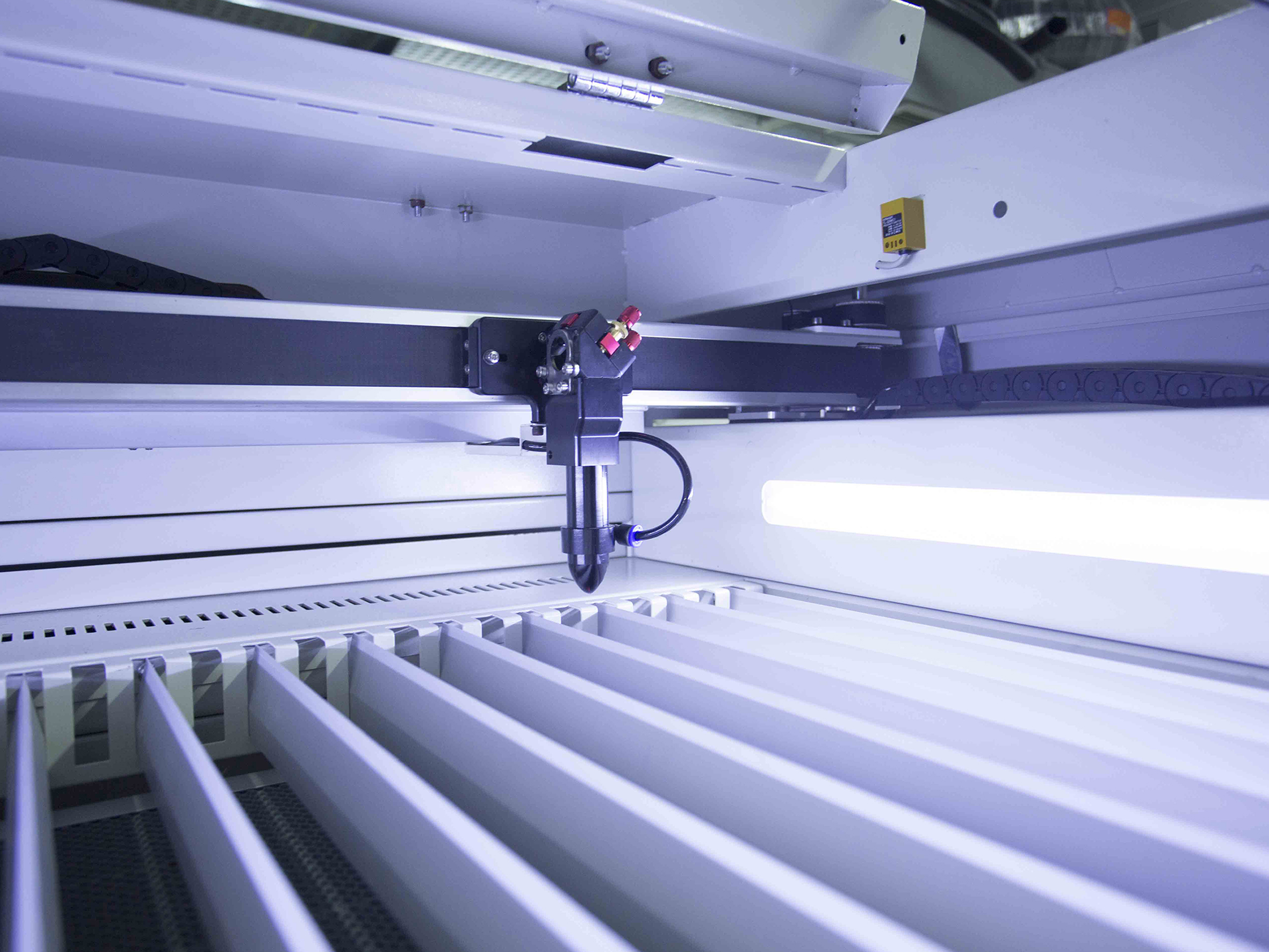

Conception d'emballage propre

La poussière est l'un des principaux ennemis des machines de gravure et de découpe laser. La fumée et les particules sales ralentissent la machine laser et nuisent aux résultats. La conception Clean Pack du NOVA10 protège le rail de guidage linéaire de la poussière, réduit efficacement la fréquence de maintenance et garantit un résultat nettement meilleur.

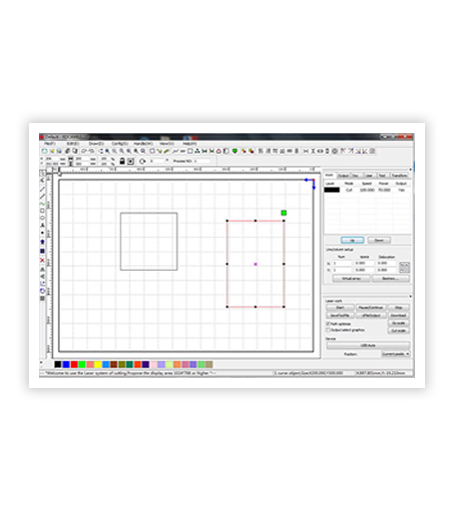

Logiciel AEON ProSMART

Le logiciel Aeon ProSmart est convivial et offre des fonctionnalités complètes. Vous pouvez configurer les détails techniques et l'utiliser très facilement. Il prend en charge tous les formats de fichiers courants et permet de travailler directement avec CorelDraw, Illustrator et AutoCAD. Vous pouvez même utiliser une fonction d'impression directe, comme la combinaison de touches Ctrl+P.

Multi-communication

La nouvelle NOVA10 est dotée d'un système de communication multi-débit haut débit. Vous pouvez vous connecter à votre machine par Wi-Fi, câble USB ou câble réseau LAN, et transférer vos données par clé USB. Les machines disposent d'une mémoire de 256 Mo et d'un panneau de commande couleur convivial. En cas de panne de courant, la machine fonctionne hors ligne et s'arrête.

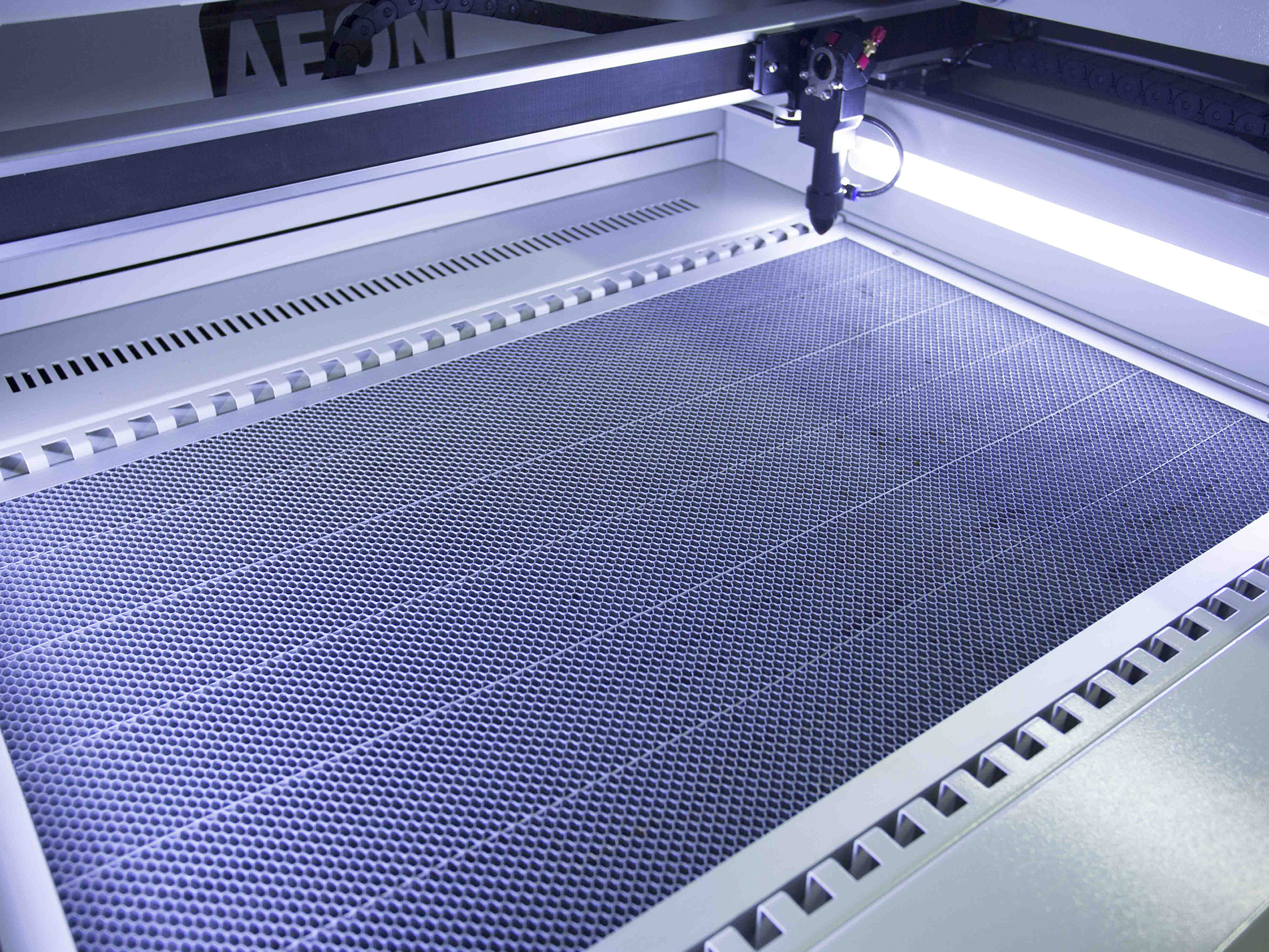

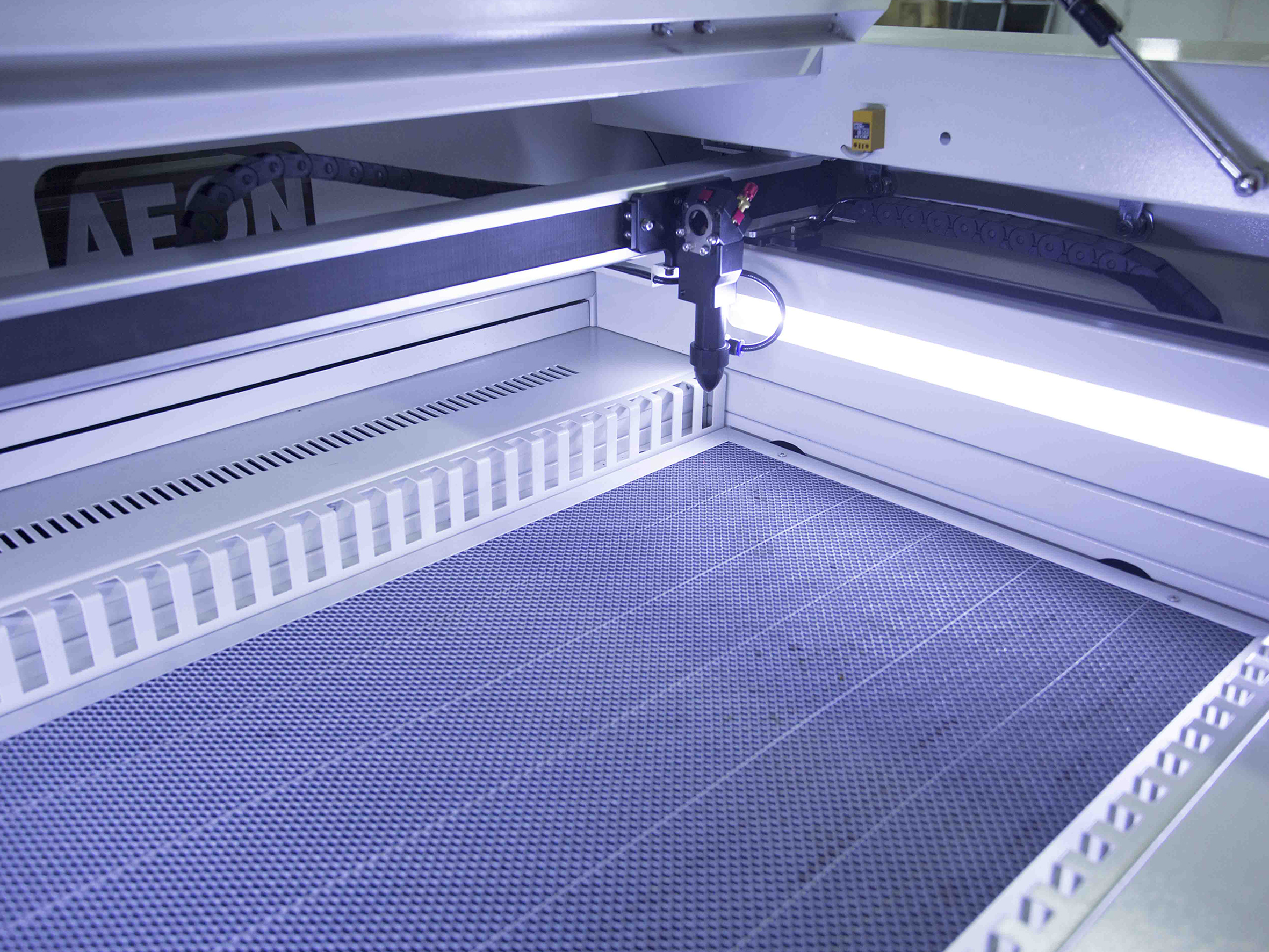

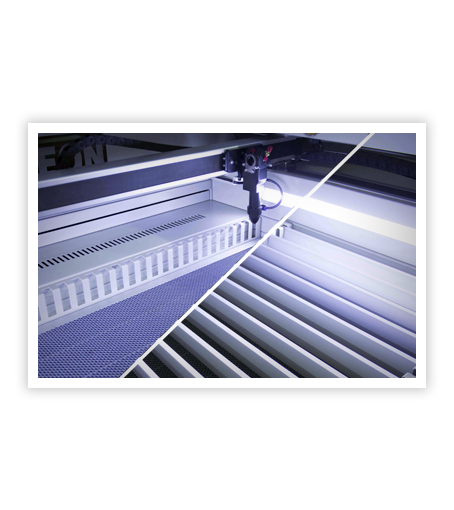

Conception de table multifonctionnelle

Selon le matériau utilisé, vous devrez utiliser différentes tables de travail. La nouvelle NOVA10 est équipée de série d'une table HoneyComb et d'une table à lames. L'aspiration est assurée sous la table HoneyComb. Grâce à sa conception traversante, l'accès est facile pour les matériaux de grande taille.

*Les modèles Nova disposent d'une plate-forme élévatrice haut/bas de 20 cm avec la table d'aspiration.

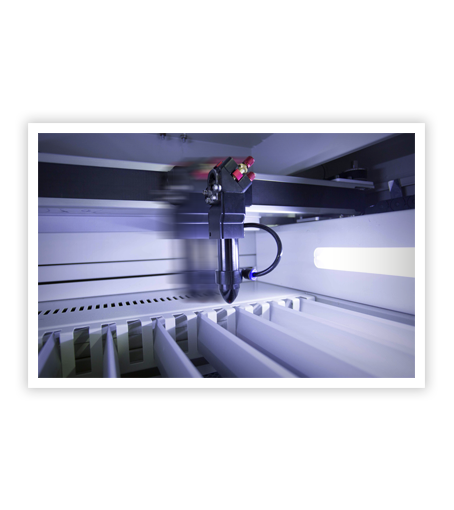

Plus rapide que les autres

La nouvelle NOVA10 offre un fonctionnement ultra-efficace. Grâce à ses moteurs pas à pas numériques haute vitesse, ses guides linéaires fabriqués à Taïwan et ses roulements japonais, elle offre une vitesse de gravure maximale de 1 200 mm/s et une vitesse de découpe de 300 mm/s avec une accélération de 1,8 G. Le meilleur choix du marché.

Corps fort, séparable et moderne

Le nouveau Nova10 a été conçu par AEON Laser. Il est le fruit de dix années d'expérience et des retours clients. Son corps est séparable en deux parties pour faciliter le déplacement de toute porte de 80 cm. Les LED à gauche et à droite éclairent parfaitement l'intérieur de la machine.

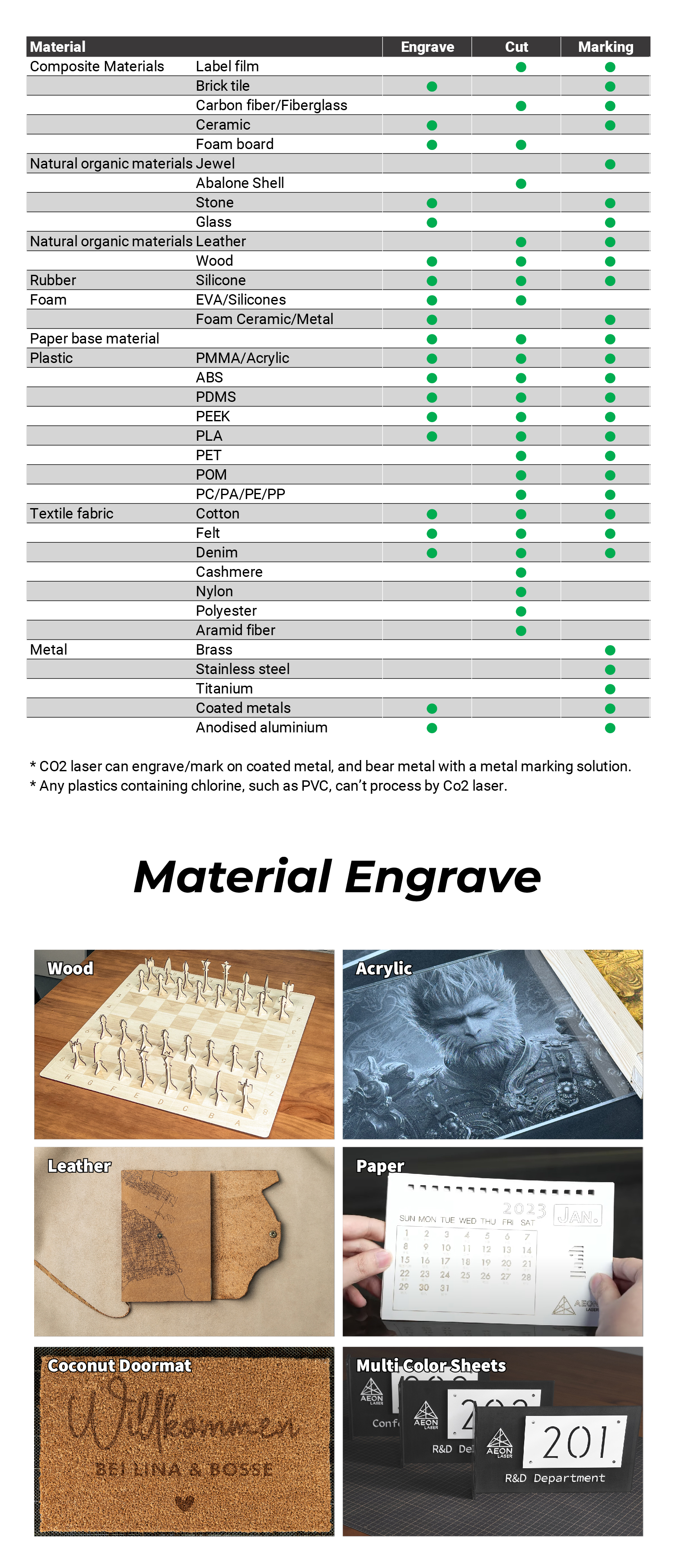

Applications matérielles

| Découpe laser | Gravure au laser |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| |

| |

| |

| |

|

*Ne peut pas couper les bois durs comme l'acajou

*Les lasers CO2 ne marquent les métaux nus que lorsqu'ils sont anodisés ou traités.

| Spécifications techniques : | |

| Zone de travail : | 1000*700mm |

| Tube laser : | 60 W/80 W/100 W (100 W nécessitent une rallonge de tube) |

| Type de tube laser : | Tube en verre scellé au CO2 |

| Hauteur de l'axe Z : | 200 mm |

| Tension d'entrée : | 220 V CA 50 Hz/110 V CA 60 Hz |

| Puissance nominale : | 1200W-1300W |

| Modes de fonctionnement : | Mode raster, vectoriel et combiné optimisé |

| Résolution: | 1000 DPI |

| Vitesse de gravure maximale : | 1200 mm/sec |

| Vitesse d'accélération : | 1,8 G |

| Contrôle optique laser : | 0-100% défini par logiciel |

| Taille minimale de gravure : | Caractère chinois 2,0 mm x 2,0 mm, lettre anglaise 1,0 mm x 1,0 mm |

| Précision de localisation : | <=0,1 |

| Épaisseur de coupe : | 0-10 mm (selon les différents matériaux) |

| Température de fonctionnement : | 0-45°C |

| Humidité ambiante : | 5 à 95 % |

| Mémoire tampon : | 128 Mo |

| Logiciels compatibles : | CorelDraw/Photoshop/AutoCAD/Tous types de logiciels de broderie |

| Système d'exploitation compatible : | Windows XP/2000/Vista, Win7/8//10, Mac OS, Linux |

| Interface informatique : | Ethernet/USB/WIFI |

| Table de travail: | Table de bar en nid d'abeille et aluminium |

| Circuit de refroidissement: | refroidissement par eau |

| Pompe à air : | pompe à air externe 135 W |

| Ventilateur d'extraction : | Souffleur externe 750W |

| Dimensions de la machine : | 1520 mm * 1295 mm * 1025 mm |

| Poids net de la machine : | 420 kg |

| Poids de l'emballage de la machine : | 470 kg |